One Board Supporting the Sky

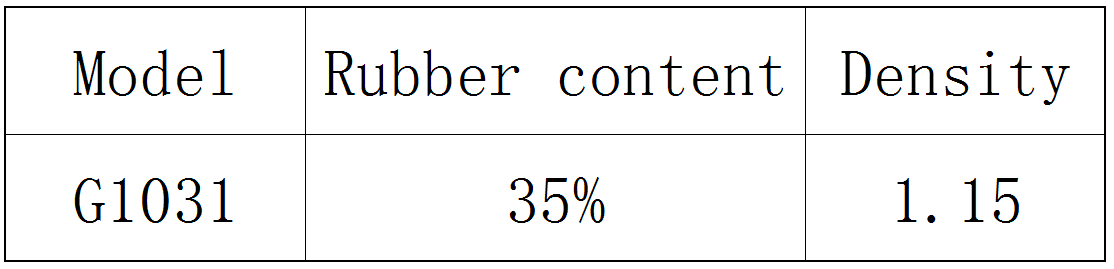

Quality Inspection For Laminated Film Packaging - G1031 Butyl Adhesive with Rubber Content Up to 35% – Gooban

Quality Inspection For Laminated Film Packaging - G1031 Butyl Adhesive with Rubber Content Up to 35% – Gooban Detail:

Butyl Rubber Formula

Carbon black: the influence of carbon ink on the physical properties of ordinary butyl rubber is basically the same as that of halogenated butyl rubber.

Softener: most butyl rubber uses petroleum oils such as paraffin oil, paraffin and ester plasticizers as softeners.

White fillers: like carbon black, white fillers have small particle size, good reinforcement effect, and large tensile strength, tensile stress, tear strength, hardness, etc; Large particle size is detrimental to tear resistance, flexion resistance and wear resistance.

Vulcanization system: in addition to general sulfur vulcanization, butyl rubber also has various vulcanization systems, which can be selected according to different uses. Especially for halogenated butyl rubber, it can be vulcanized with sulfur, quinone and resin through double bonds like diene rubber. In addition, it can also be vulcanized with metal oxide, dithiocarbamate metal salt and thiourea through halogen group, and peroxide vulcanization can be used for brominated butyl rubber.

Customization advantage: relying on the professional technical team, we can customize products according to the different needs of customers. Color, shape, size, temperature and humidity of application environment, etc. When you put forward your demand scenarios and product requirements, we will adjust the product formula to meet your product requirements. (with what · up screenshot)

Product Characteristics

The relevant properties of butyl rubber are supplemented. These properties also exist in butyl adhesive

(1) Air permeability

The dispersion speed of the gas in the polymer is related to the thermal activity of the polymer molecules. The side methyl groups in the butyl rubber molecular chain are densely arranged, which limits the thermal activity of the polymer molecules. Therefore, the gas permeability is low and the gas tightness is good.

(2) Thermal invariance

Butyl rubber vulcanizates have excellent heat resistance and invariability. Sulfur vulcanized butyl rubber can be used in the air for a long time at 100 ℃ or slightly lower temperature. The application temperature of resin vulcanized butyl rubber can reach 150 ℃ – 200 ℃. The thermal oxygen aging of butyl rubber belongs to degradation type, and the aging trend is softening.

(3) Energy absorption

The molecular structure of butyl rubber is short of double bonds, and the dispersion density of side chain methyl groups is large, so it has excellent characteristics of receiving vibration and impact energy. The rebound characteristics of butyl rubber are not more than 20% within a wide temperature range (- 30-50 ℃), which clearly indicates that the ability of butyl rubber to receive mechanical functions is superior to other rubbers. The damping property of butyl rubber at high deformation speed is inherent in the polyisobutylene segment. To a large extent, it is not affected by the application temperature, degree of unsaturation, vulcanization shape and formula change. Therefore, butyl rubber was an ideal material for sound insulation and vibration reduction at that time.

(4) Low temperature property

The space structure of butyl rubber molecular chain is spiral. Although there are many methyl groups, each pair of methyl groups scattered on both sides of the spiral are staggered by an angle. Therefore, the butyl rubber molecular chain is still quite gentle, with low glass transition temperature and good elasticity.

(5) Ozone and aging resistance

The high saturation of butyl rubber molecular chain makes it have high ozone resistance and weather aging resistance. The ozone resistance is about 10 times higher than that of natural rubber.

(6) Chemical invariance

The high saturated structure of butyl rubber makes it have high chemical invariance. Butyl rubber has excellent corrosion resistance to most inorganic acids and organic acids. Although it is not resistant to concentrated oxidizing acids, such as nitric acid and sulfuric acid, it can resist non oxidizing acids and medium concentration oxidizing acids, as well as alkali solutions and oxidation recovery solutions. After soaking in 70% sulfuric acid for 13 weeks, the strength and elongation of butyl rubber were hardly lost, while the functions of natural rubber and styrene butadiene rubber were severely reduced.

(7) Electric function

The electrical insulation and corona resistance of butyl rubber are better than that of simple rubber. The volume resistivity is 10-100 times higher than that of simple rubber. The dielectric constant (1kHz) is 2-3 and the power factor (100Hz) is 0.0026.

(8) Water absorption

The water penetration rate of butyl rubber is extremely low, and the water absorption rate at normal temperature is lower than that of other rubber, only 1 / 10-1 / 15 of the latter.

Product detail pictures:

Related Product Guide:

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for Quality Inspection For Laminated Film Packaging - G1031 Butyl Adhesive with Rubber Content Up to 35% – Gooban , The product will supply to all over the world, such as: Adelaide, San Francisco, South Korea, We aim to become the modern enterprise with the commercial ideal of Sincerity and confidence and with the aim of Offering customers the most sincere services and best quality products. We sincerely ask for your unchanged support and appreciate your kind advice and guidance.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.