Products

2022 Latest Design Blown Film Packaging - Brominated Butyl Rubber (BIIR) – Gooban

2022 Latest Design Blown Film Packaging - Brominated Butyl Rubber (BIIR) – Gooban Detail:

Product Characteristics

Butyl rubber is a linear polymer with isobutylene as the main body and a small amount of isoprene. On the main chain of butyl rubber molecule, every other methylene group, there are two methyl groups arranged in a spiral shape around the main chain, causing a large steric hindrance, making the molecular structure of butyl rubber compact and the molecular chain flexible relatively poor. However, it also makes butyl rubber excellent in air tightness, ranking first among all rubbers.

In addition to excellent air tightness, butyl rubber vulcanizates also have excellent heat resistance. Sulfur vulcanized butyl rubber can be used in air for a long time at 100 ℃ or slightly lower temperature. The service temperature of butyl rubber vulcanized with resin can reach 150-200 ℃. The thermal oxygen aging of butyl rubber belongs to degradation type, and the aging tends to soften. Due to the low unsaturation of the molecular chain of butyl rubber and the inert chemical reaction, butyl rubber has good heat and oxygen aging resistance.

Trade mode: brominated butyl rubber is our agent product. The minimum order is 20 tons.

Application

1. Application in automobile tire and power vehicle tire:

Butyl rubber has excellent heat resistance and tear resistance. The inner tubes (including motorcycles and bicycles) made of butyl rubber can still maintain good tensile and tear strength after long-term exposure to the thermal environment, which reduces the risk of bursting during use. The butyl rubber inner tube can still ensure the maximum tire life and safety under high temperature conditions or under inflated conditions. The smaller tear can reduce the size of the hole and make the repair of the butyl rubber inner tube easier and convenient. The excellent oxidation resistance and ozone resistance of butyl rubber make butyl rubber inner tube have excellent degradation resistance, and its durability and service life are better than natural rubber inner tube. The extremely low air permeability of butyl rubber enables the inner tube made of it to be kept at the correct inflation pressure for a long time. This unique performance enables the tire outer tube to wear evenly and ensures the best crown life. Extend the service life of the outer tire, increase the stability and safety of driving, reduce the rolling resistance, and then reduce the fuel consumption to achieve the purpose of energy saving.

2. Application in medical bottle stopper:

Medical bottle stopper is a special rubber product for sealing and packaging that directly contacts with drugs. Its performance and quality directly affect the effectiveness, safety, quality stability and convenience of drugs. Medical corks are often sterilized under high temperature and high pressure conditions or in various disinfectants, and sometimes they need to be stored for a long time under low temperature conditions. Therefore, there are strict requirements on the chemical properties, physical mechanical properties and biological properties of the rubber. Since the bottle stopper is in direct contact with the drug, it may contaminate the drug due to the dispersion of the extractable substance in the bottle stopper into the drug, or reduce the activity of the drug due to the absorption of some components in the drug by the bottle stopper. Butyl rubber not only has low permeability, but also has excellent oxidation resistance, acid and alkali resistance, heat resistance and chemical damage resistance. After the butyl rubber bottle stopper is used, the pharmaceutical factory can simplify the sub packaging process, use the open aluminum cap, eliminate the sealing wax and reduce the cost, and can also facilitate the injection use.

3. Other applications:

In addition to the above uses, butyl rubber has the following uses: (1) lining of chemical equipment. Due to its excellent chemical corrosion resistance, butyl rubber has become the preferred material for corrosion resistant lining of chemical equipment. The volume swelling of butyl rubber in various solvents is very low, which is one of the important reasons why butyl rubber is used in this field. (2) Protective clothing and protective articles. Although many plastic materials have good isolation and protection performance, only elastic materials can give consideration to the flexibility necessary for low permeability and comfortable clothing. Because of its low permeability to liquids and gases, butyl rubber is widely used in protective clothing, ponchos, protective covers, gas masks, gloves, rubber overshoes and boots.

Preparation

There are two main production methods of ordinary butyl rubber: slurry method and solution method. The slurry method is characterized by using chloromethane as diluent and water-alcl3 as initiator. At low temperature of – 100 ℃, isobutylene and a small amount of isoprene undergo cationic copolymerization. The polymerization process requires the use of catalysts. In order to improve the efficiency of catalysts, it is necessary to use cocatalysts to initiate polymerization in many cases. The production technology is monopolized by foreign American companies and German companies. The production process of butyl rubber by slurry method mainly includes four steps: polymerization, product refining, recycling and kettle cleaning. The solution method was developed by Russian taoriati synthetic rubber company and Italian company. The technical feature is that the complex of alkyl aluminum chloride and water is used as initiator to copolymerize isobutene and a small amount of isoprene in hydrocarbon solvent (such as isopentane) at the temperature of – 90 to – 70 ℃. The main process of butyl rubber production by solution method includes preparation, cooling, polymerization of initiator system and mixed ingredients, mixing of rubber solution, degassing and stripping, recovery and refining of solvent and unreacted monomer, post-treatment of rubber, etc. the main auxiliary processes include refrigeration, reactor cleaning, additive preparation, etc.

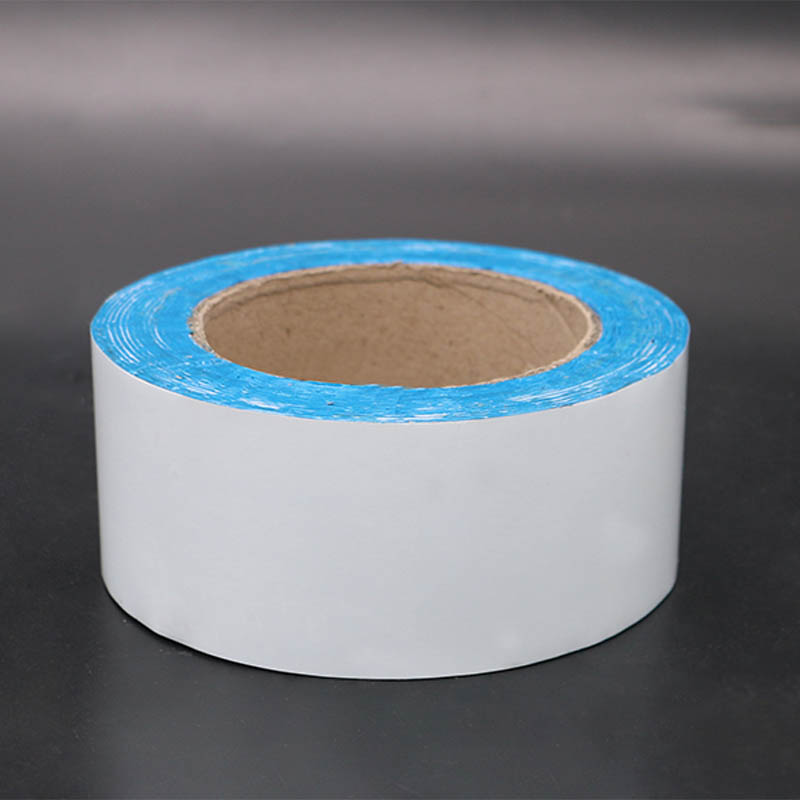

Product detail pictures:

Related Product Guide:

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for 2022 Latest Design Blown Film Packaging - Brominated Butyl Rubber (BIIR) – Gooban , The product will supply to all over the world, such as: Muscat, Sudan, Mauritius, Our solutions have national accreditation requirements for qualified, good quality products, affordable value, was welcomed by individuals all over the world. Our products will continue to improve inside the order and appear forward to cooperation with you, Definitely should any of those goods be of curiosity to you, be sure to letus know. We'll be satisfied to supply you a quotation up on receipt of the detailed needs.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.